|

* Depends upon weapon configuration - standard configuration with 7kg disc is given.

Chassis and Armour

The chassis is constructed almost universally with 1mm wall 1" box section steel, welded together with a mig welder. Some key parts are made of thicker wall (up to 3mm) material. 2mm thick plates are used for the front part of the motor mounts. M6 bolts are used everywhere possible, except on parts of the Series 4 pneumatics where M8 was required. The Series 5 chassis is essentially the same as Series 4, but slightly wider, longer, and changed in shape at the rear of the robot to keep the wheels in contact with the ground more. For Series 6, the major change was to turn the front area of the chassis into an Interchangable Weapons bay, and also to reduce weight.

For Series 4, the armour was 6mm polycarbonate (tuffak). Repairs were made to this using Araldite 2026 - note that Vantico do not supply small quantities of this adhesive, speak to Buck & Hickman or Aeropia. It is held to the chassis with M6 countersunk bolts, which screw into M6 plain nuts welded to the chassis. The access flap is held down using neodymium magnets. For Series 5 and Extreme 1 we stayed at 6mm polycarbonate, but laminated with Titanium over critical areas. The link access door also has been moved, to the back of the robot to keep it away from the weapon and allow access whatever way up we are. Series 6 sees us varying the thickness of armour depending upon which weapon configuration we are using, and adding thicker plates of Titanium over the electronics and along the sides.

For Series 4, the armour was 6mm polycarbonate (tuffak). Repairs were made to this using Araldite 2026 - note that Vantico do not supply small quantities of this adhesive, speak to Buck & Hickman or Aeropia. It is held to the chassis with M6 countersunk bolts, which screw into M6 plain nuts welded to the chassis. The access flap is held down using neodymium magnets. For Series 5 and Extreme 1 we stayed at 6mm polycarbonate, but laminated with Titanium over critical areas. The link access door also has been moved, to the back of the robot to keep it away from the weapon and allow access whatever way up we are. Series 6 sees us varying the thickness of armour depending upon which weapon configuration we are using, and adding thicker plates of Titanium over the electronics and along the sides.

Drivetrain and Wheels

The first stage gearing uses steel MOD2 gears from HPC; a 12 tooth pinion is fitted to the motor with a solid 5mm dowel pin, and the (machined and lightened) 48 tooth spur gear is bolted to a machined down go-kart clutch. This gives a first stage gearing of 1:4. For Series 4 the intermediate gear assembly ran on the roller bearing contained in the go-kart clutch, which sat on a custom spacer on a 17mm silver steel axle. This tended to move around during fights, and the spacer wore very quickly, we have changed to a longer axle with a pair of bearings. Drive is transferred from the 16t clutch pinion to the 70t main drive sprockets via kart chain, giving a second stage gearing of 1:4.375, and thus the overall gear ratio is 1:17.5. An idler bearing is used to ensure sufficent chain wraps around the kart clutch pinion, as it was found to slip under stall conditions without it.

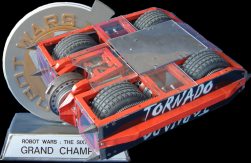

Our Series 4 wheels gave us some problems (it was difficult to get the kart sprocket centred on the wheel), and were changed for Series 5. Instead of the custom aluminium drive plate/custom machined nylon drive block/standard nylon kart wheel with integral bearing setup used in Series 4, our new wheels use as many off the shelf parts as possible. The sprocket is attached to a custom axle tube with a standard kart sprocket carrier, and this axle tube uses a pair of needle roller bearings on a 14mm silver steel axle. The wheels for Series 5 are standard nylon two piece kart front wheels, but without integral bearings, attached to the axle tube with a standard kart hub carrier. It makes the wheels much easier to build, and ensures that the sprockets stay absolutely conicentric on the axle! The wheel design remains the same in Series 6, but uses one piece aluminium wheels rather than two piece nylon, and Titanium axles to save weight. As before, tyres are racing go-kart fronts (10" diameter), the type chosen to suit arena conditions at the event, obtained for free from kart tracks after the racers have thrown them out.

Our Series 4 wheels gave us some problems (it was difficult to get the kart sprocket centred on the wheel), and were changed for Series 5. Instead of the custom aluminium drive plate/custom machined nylon drive block/standard nylon kart wheel with integral bearing setup used in Series 4, our new wheels use as many off the shelf parts as possible. The sprocket is attached to a custom axle tube with a standard kart sprocket carrier, and this axle tube uses a pair of needle roller bearings on a 14mm silver steel axle. The wheels for Series 5 are standard nylon two piece kart front wheels, but without integral bearings, attached to the axle tube with a standard kart hub carrier. It makes the wheels much easier to build, and ensures that the sprockets stay absolutely conicentric on the axle! The wheel design remains the same in Series 6, but uses one piece aluminium wheels rather than two piece nylon, and Titanium axles to save weight. As before, tyres are racing go-kart fronts (10" diameter), the type chosen to suit arena conditions at the event, obtained for free from kart tracks after the racers have thrown them out.

Radio Gear

The radio gear is basic and cheap; the 40MHz Hi-Tec Ranger III transmitter coupled to the Hi-Tec 8 channel dual conversion receiver. The transmitter and receiver can be modified to transmit and receive a full seven channels, and this was done to all our radio gear (including spares). The standard 7 channel chips are used on the circuit boards inside the units, just the extra channels are disabled! No interference problems were found with this setup, provided we had a good aerial. The aerial was made removable so it could be replaced if damaged, and did we have to replace it! From Series 5 we changed the aerial to a piece of piano wire mounted at the rear of the robot, making it more robust. To save weight and make receiver crystal changing quicker in Series 6, the AA batteries were eliminated from the receiver box (power now being supplied from the main supply via a regulator) and a new quick access receiver mount made.

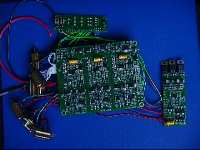

Electronics and Speed Control - Series 4

The Pulse-Position modulation signal from the modified receiver was passed to a custom failsafe and decoder board. This checked that all elements of the signal were correct, and we have suffered no runaways or loss of control. A custom decoder system (using simple analogue and digital IC's, no PIC) converted the control signals to operate the robot. The speed controller was a custom design, using five 60 amp FETs on each leg of a pair of H-bridges, giving us 300 amps capability. Building almost all of the electronic parts ourselves allowed us to have fine control over the handling and dynamics of the robot, which is what makes nearly 80kg of metal handle and respond like a good radio controlled kit car.

The motors were the Bosch GPA 750W, the only modifications being a few welds to the casing. Power came from three 12V Hawker SBS15 batteries wired in series to give 36V. Fork lift truck fuses (200A) were used to prevent fire in the event of a short circuit, and the removable link was made up from a pair of AMP automotive connectors, rated at 75amps each, giving us 100A continuous current capability (including the derating for putting them in a block).

The motors were the Bosch GPA 750W, the only modifications being a few welds to the casing. Power came from three 12V Hawker SBS15 batteries wired in series to give 36V. Fork lift truck fuses (200A) were used to prevent fire in the event of a short circuit, and the removable link was made up from a pair of AMP automotive connectors, rated at 75amps each, giving us 100A continuous current capability (including the derating for putting them in a block).

Electronics and Speed Control - Series 5

Again we took the PPM signal from the receiver to a decoder and controller driver box, but this year all the circuitry was built on proper PCBs. The new speed controllers are modular, so we built easily replaced (identical) spares, given both our Series 4 controller AND the half relays/half FETs backup expired within the same week! We used either the Hawker SBS15 or Kiel batteries, although we found performance problems with the Kiels and obtained some new Hawker Genesis batteries instead - these were found to perfom much better. The fuse arrangement and removable link was slightly different (to save weight), while the motors were exactly the same as last year.

Electronics and Speed Control - Series 6

The controllers built for Series 5 have proved very reliable, and so we have continued to run them. We have changed to Hawker Odyssey batteries (essentially the same as the Genesis battery but warrantied for deep cyclic discharge). We

have added a speed controller capacitor charging plug beside our link in an effort to improve the reliability and life of the link contacts.

Weapon - Pneumatics - Series 4

The pneumatic system was based around a pneumatic ram obtained from an old loudspeaker production line; out of the many available to us it had the largest bore with reasonable stroke. Large bore piping was used where possible, along with a fire extinguisher buffer tank and fast-exhaust valve. A single 5-port valve was used to control the system, while gas was supplied from a pair of oxygen bottles via a custom regulator. Unfortunately Mentorn had issues with our high pressure side, meaning we had very few shots, and thus the weapon was little more than token. See our Pneumatics Information page.

Weapon - 7kg Spinning Disc - Series 5 and Extreme 1

We looked at what space was available in the chassis, what weight we had left, and what we had the time and facilities to build. Any new weapon would have to work with the robot either way up, and given our knowledge of motors and electronics, an electric powered spinning disc came out clear favourite. We looked at the other spinning disc robots out there - Hypnodisc, although effective, tends to waste half the storted energy from the disc in sending itself flying across the arena in the opposite direction to their opponent. We didn't want to waste any of our stored energy, and so we mounted our disc vertically (like Pussycat). The reaction due to impact pushes Tornado into the arena floor, we get a reaction force back from the arena floor for free (Newton's 3rd Law) and thus transfer the majority of our stored energy to our opponent.

In typical Tornado style we use a 24V Bosch GPA 750W motor run at 36V to power it, and it is geared to give a maximum speed of about 2500rpm. It is driven using three V belts, to allow for belt failure and wear (Hypnodisc had problems with belts in Series 3), while the motor is mounted on an adjustable cradle to take up any slack in the belts. We expected the weapon motor to spend a lot of time stalled, so the motor pulley is equiped with an optical sensor that allows us to back the current limit off automatically when the motor is not turning, but ramp it up very quickly as soon as it starts turning again.

In typical Tornado style we use a 24V Bosch GPA 750W motor run at 36V to power it, and it is geared to give a maximum speed of about 2500rpm. It is driven using three V belts, to allow for belt failure and wear (Hypnodisc had problems with belts in Series 3), while the motor is mounted on an adjustable cradle to take up any slack in the belts. We expected the weapon motor to spend a lot of time stalled, so the motor pulley is equiped with an optical sensor that allows us to back the current limit off automatically when the motor is not turning, but ramp it up very quickly as soon as it starts turning again.

Weapon - Interchangable - Series 6 and Extreme 2

Good as the 7kg disc is, it is not ideal against all opponents. We are making use of the Interchangeable Weapons rule, and have developed weapons designed to beat opponents that have given us problems in the past. The front of Tornado's chassis has been modified to form a proper interchangeable weapons bay, allowing the easy and quick fitment of each of our weapons options.

#1 - 7kg Spinning Disc. This is our primary, main weapon. It's essentially the same disc as used in Series 5 and Extreme 1, but built into a removable cradle.

#2 - Spiked Scoop (Charity Event Pushing Blade). This is the weapon we use at most charity events. It was built out of scrap steel, and is very heavy and very strong!

#3 - Fixed Spike. This weapon is a very basic, Series 1 or 2 ramming spike - but taken to the absolute limit!

#4 - ACW (Anti Crusher Weapon). Our encounters with Razer have proved that Tornado is extremely vunerable to crushing robots. We designed and built this weapon specifically to counter them.

For more information, see our Build Diary. In parts of the build diary you will find references to our ASW (Anti Spinner Weapon) and AAW (Anti Axe Weapon) - these were ruled illegal by Mentorn's technical crew. Oh well! ;)

| Home ||

Build Diary ||

Official Merchandise ||

Site Map ||

E-Mail |

|

For Series 4, the armour was 6mm polycarbonate (tuffak). Repairs were made to this using Araldite 2026 - note that Vantico do not supply small quantities of this adhesive, speak to Buck & Hickman or Aeropia. It is held to the chassis with M6 countersunk bolts, which screw into M6 plain nuts welded to the chassis. The access flap is held down using neodymium magnets. For Series 5 and Extreme 1 we stayed at 6mm polycarbonate, but laminated with Titanium over critical areas. The link access door also has been moved, to the back of the robot to keep it away from the weapon and allow access whatever way up we are. Series 6 sees us varying the thickness of armour depending upon which weapon configuration we are using, and adding thicker plates of Titanium over the electronics and along the sides.

For Series 4, the armour was 6mm polycarbonate (tuffak). Repairs were made to this using Araldite 2026 - note that Vantico do not supply small quantities of this adhesive, speak to Buck & Hickman or Aeropia. It is held to the chassis with M6 countersunk bolts, which screw into M6 plain nuts welded to the chassis. The access flap is held down using neodymium magnets. For Series 5 and Extreme 1 we stayed at 6mm polycarbonate, but laminated with Titanium over critical areas. The link access door also has been moved, to the back of the robot to keep it away from the weapon and allow access whatever way up we are. Series 6 sees us varying the thickness of armour depending upon which weapon configuration we are using, and adding thicker plates of Titanium over the electronics and along the sides.

Our Series 4 wheels gave us some problems (it was difficult to get the kart sprocket centred on the wheel), and were changed for Series 5. Instead of the custom aluminium drive plate/custom machined nylon drive block/standard nylon kart wheel with integral bearing setup used in Series 4, our new wheels use as many off the shelf parts as possible. The sprocket is attached to a custom axle tube with a standard kart sprocket carrier, and this axle tube uses a pair of needle roller bearings on a 14mm silver steel axle. The wheels for Series 5 are standard nylon two piece kart front wheels, but without integral bearings, attached to the axle tube with a standard kart hub carrier. It makes the wheels much easier to build, and ensures that the sprockets stay absolutely conicentric on the axle! The wheel design remains the same in Series 6, but uses one piece aluminium wheels rather than two piece nylon, and Titanium axles to save weight. As before, tyres are racing go-kart fronts (10" diameter), the type chosen to suit arena conditions at the event, obtained for free from kart tracks after the racers have thrown them out.

Our Series 4 wheels gave us some problems (it was difficult to get the kart sprocket centred on the wheel), and were changed for Series 5. Instead of the custom aluminium drive plate/custom machined nylon drive block/standard nylon kart wheel with integral bearing setup used in Series 4, our new wheels use as many off the shelf parts as possible. The sprocket is attached to a custom axle tube with a standard kart sprocket carrier, and this axle tube uses a pair of needle roller bearings on a 14mm silver steel axle. The wheels for Series 5 are standard nylon two piece kart front wheels, but without integral bearings, attached to the axle tube with a standard kart hub carrier. It makes the wheels much easier to build, and ensures that the sprockets stay absolutely conicentric on the axle! The wheel design remains the same in Series 6, but uses one piece aluminium wheels rather than two piece nylon, and Titanium axles to save weight. As before, tyres are racing go-kart fronts (10" diameter), the type chosen to suit arena conditions at the event, obtained for free from kart tracks after the racers have thrown them out.

The motors were the Bosch GPA 750W, the only modifications being a few welds to the casing. Power came from three 12V Hawker SBS15 batteries wired in series to give 36V. Fork lift truck fuses (200A) were used to prevent fire in the event of a short circuit, and the removable link was made up from a pair of AMP automotive connectors, rated at 75amps each, giving us 100A continuous current capability (including the derating for putting them in a block).

The motors were the Bosch GPA 750W, the only modifications being a few welds to the casing. Power came from three 12V Hawker SBS15 batteries wired in series to give 36V. Fork lift truck fuses (200A) were used to prevent fire in the event of a short circuit, and the removable link was made up from a pair of AMP automotive connectors, rated at 75amps each, giving us 100A continuous current capability (including the derating for putting them in a block).