|

CLICK ON THE THUMBNAILS TO VIEW A LARGER IMAGE | Back to previous entry - Building Begins | 19/5/00 - Bad bad bad bad news. Rung Derek Foxwell to clarify a few points regarding the new qualifying entry form - and we have some big changes to make! Our pneumatics system is nowhere near up to what is required - the welding cylinders we planned to use as main supply tanks are not good enough as they are not designed as a) refillable or b) to take Nitrogen! Also it is likely that gas charging will be done by Air Products Ltd, who will refuse to fill anything not up to the job! Our threads (on all of our tanks etc) must be to BS standard - i.e. BSP taper threads, not parallel as we have used in places (as the taps/dies are cheaper!). All parts of the system must be designed for the purpose - i.e. the supply tanks must be designed to store the gas used, and the connectors and hoses to run at the pressure used. The "pressure relief valve" covers two components - a venting tap on the low pressure side, and a burst valve on the high pressure part of the system, both within the robot! Also our chosen "bridgeable link" switch (a car battery isolator) is not favoured, as the key can be broken in combat; better is a household mains fusebox fuse, with the fuse bridged, as this can still be removed if damaged. On the plus side, the "carrying cradle" is the on desk drivetrain demo thing, locking pins are not needed on the spike if it has a metal cover that protects its whole travel, and our home built failsafes are OK so long as they pass the test (white RF noise generator). 21/5/00 - Went to the Kart track at Buckmore Park again on the way back from my parents house in Kent. Managed to get a car bootfull (literally) of tyres, including at least six wets! 22/5/00 - Unloaded the tyres got yesterday - another 29 including 7 wets, but one of the slicks is worn down to the canvas and so is useless. With the number we have now, we don't really care... Also measured up to see what space is available for gas supply tanks.

23/5/00 - Investigated several pressure resevoir companies - it looks like we are going to be able to get the supply tanks custom made! Also got some more driving practice in, and did some preliminary measurements for the armour. 24/5/00 - Looks like we're going to be able to get suitable main supply tanks for about 30 quid each, with adaptors for 15 quid. We'll need to get a regulator (maybe £60), but it's going to be a lot less painful than we thought! 25/5/00 - Rung Life Support Engineering regarding the supply tanks - we are getting three tanks and two adaptors made up. Also interestingly they say that parallel BSP threads are to British Standard and therefore should not be outlawed by the wording of the rules! I rang Derek about this, and it seems he was looking at the spec for BSG (British Standard Gas) rather than BSP (British Standard Pipe) which is a lot coarser and therefore OK as a parallel thread. Spent the evening going over the chassis, grinding and cleaning it up where necessary, in preparation for mounting the armour. Got a bit more driving practice... 27/5/00 - Not much robot work - but that's because we spent the day chasing the rust out of Bryan's Land Rover chassis. Ended up with half a bucketfull of iron oxide and a burnt out angle grinder! Met the owner of the cafe site during driving practice, who is happy for us to run the RC cars there. 28/5/00 - Bryan bought himself a grinder, and with his replacement brushes we got mine going again too. Cleaned up the rest of the (robot) chassis, and started cutting the armour. (The Land Rover is too far gone and a replacement rear crossmember has been ordered!) 29/5/00 - Contrary to what Derek Foxwell told me on the 27/3/00, the Kiel batteries are now banned from Robot Wars. We still however do not recommend that you buy the Hawkers from Display. (However, at the filming of the Series 4 Derek told me that a competitor had brought a Kiel in for him to test, and they are now officially approved for Robot Wars use!) 30/5/00 - Continued with the armour, and managed to get some of the mounting holes on the rear section drilled. Yet more driving practice (but with a real purpose this time, to weedle out the dodgy RC batteries, then dismantle and deal with them!). 5/6/00 - Dave is back from his storm chasing holiday, and guess what, he saw the lot: Tornadoes, golf ball hail, ball lightning... Have a look at some of his holiday photos! 6/6/00 - Filled in and submitted the Mentorn Qualifying round entry form. Started filling in the Robots@War entry forms, but we have a query about liability if the arena were to fail... Managed to drill much of the armour in the evening. Dave has found and solved an instability problem in the decoder board. 7/6/00 - Got a reply from Dave Jones, the organiser of Robots@War. He's satisfied our query, and we'll be sending off the contract tomorrow. Also got a lot more of the armour drilled and shaped to suit the chassis. 8/6/00 - Sent off Robots@War contract. Continued drilling the armour. 11/6/00 - Welded all the armour mounting nuts onto the chassis. Bryan started making the wheel cutouts in the top and bottom armour. Worked out what connectors to use for our removeable link - we intend to use some 75A RS automotive connectors, doubled up to increase current handling. Dave finished designing and testing the step up/down power supply. Plus we got some more driving practice... 12/6/00 - Tanks arrived from Life Support Engineering - they are perfect! Bryan shortened the axles during lunch, and I ordered the removeable link parts. Spent the evening modifying the tank mounts in the chassis to take the new tanks, and making the spike screw into the ram properly. Dave built the step up/down power supply. 15/6/00 - Bryan covered the garage in little bits of plastic, as he used the router to finish cutting the holes on the bottom side of the armour. Meanwhile I cut the holes in the front section for the weapon (ram) mounts and spike. Dave completed the electronic system and demonstrated it running on a bench (from 24V), with both motors under full radio control. The control dynamics will need setting up properly, but we are now so close to our first run that we can taste it... shame Dave is going away this weekend!

20/6/00 - Started assembling the chassis. Built up (but not plumbed) the pneumatic system, installed the motors, drivetrain and wheels, and the underside armour sheet. Attached batteries to test the drivetrain - at 12V, it wheelspins when held against a wall, and required Bryan standing on it to stall it. When standing off the ground, we could not stall it with our hands... With both motors running, it can turn on the spot without problem, and (remembering there is no current limit or ESC accelleration ramp) it will pull away to top speed almost instantly! When run at 24V (probably equal to the maximum torque we will use), it is very hard to stall when held against a wall, and it left black marks on Dave's drive plus the tyres got rather warm... As for the electronics, Dave modified the decoder box (taking the current limit pots out on flying leads) and did the first test on 36V with batteries... and he blew four FETs with a big bang! The feeling is that interference on the flying leads is to blame, so we shall discard them in future (and have to open the decoder box to change the current limits).

21/6/00 - Dave rebuilt the speed controller. 22/6/00 - Started assembling electronics into chassis. Made up the fuse panel and battery clamp, and installed the speed controller, decoder box and power supply. Unfortunately it looks like we are even tighter on space than we first thought - and something has to give! We expect to have to remove one of our buffer resevoir tanks (but this will give us a spare...), move the main supply tanks, and relocate the valve(s) and regulator. We still have some parts to buy though... with only 16 days left to Robots@War, we need to get a move on!

23/6/00 - Continued with the electronics assembly, finishing the fuse panel and making up most of the high current wiring. As we have not yet decided the positioning for the removeable link, we have temporarily wired in our red keyswitch for testing. Before powering up, we noticed a spark when (accidentally!) touching +12V to the supposedly floating chassis - a ground-short was traced to one of the D-sockets in the decoder box. On power up with the robot on the bench, everything seemed to work OK! The steering is wired the wrong way round (easy to fix), and there's some instability in the control circuit somewhere (so the motors squeal), but it's not too big a problem. Worse is a lack of range (about 10m) and oscillation in the failsafe system - but there is still much to check!  24/6/00 - Dave continued checking the electronics system. It seems that the problems occur only when the speed controller is powered up or the power supply is boosting, and that they are causing interference to the radio part of the system. This is worrying, as our speed controller is not dissimilar to a 4QD, and they have no box...! We went out and bought the dual conversion Hi-Tec receiver, but it only made a small improvement. Meanwhile I made up the side bars and started work on the new spike guards. 26/6/00 - Bryan got on the phone and ordered us a regulator and burst valves, so the pneumatic system should be on course again. I worked further on the new spike guards - but my original design did not work, so a redesign was required. Dave decided a further range check was required using the new (dual conversion) receiver, so we installed all the electronics again. Walking the direction we did before (down Dave's drive), an improvement was obvious when the receiver aerial was held upright - about 20m was possible before the failsafe cut in. However, when walking in the opposite direction (out of his garden and onto the school field), we got over 100m away without any problems! Control at that distance was poor, but I couldn't even see the robot... (It was on a stand BTW, not running around on the ground!) Control at about 50m was perfect. With the aerial down in the chassis however, range was less than a metre. So, we decided to have a quick run on Dave's grass - other than a few flashes from the failsafe light, and some over helpful control ramps making it run on, we have had our first sucessful driving test under radio control! Work is still required - we need to look at motor suppresion and how we are going to mount the aerial (given we are supposed to be able to run upside down) but we are a lot happier today than we were!

27/6/00 - Did a bit more driving testing to show Bryan, and as part of it we decided a stall test against a wall was in order. Given we have only a low (about 50 amps) current limit set, we were rather suprised to see that we could get the tyres to smoke... can your robot smoke it's tyres? (Yes, that tyre is shiny because it's melted...) Otherwise, we got what is still needed to be ordered for the pneumatics sorted, and, er, tidied up Dave's garage...

28/6/00 - Ordered the remaining pneumatics parts. Worked on the spike guards and demonstration stand/trolley - until that is we (again) ran out of welding gas... Dave worked on the chargers, modifying some old PC power supplies. 29/6/00 - Majority of the remaining pneumatics parts arrived, just waiting on the regulator and burst valves now. Got more welding gas and another angle grinder (number three!). Spent the evening building the stand, designing the trolley and working on the spike guards and side bars. Dave designed our battery charger... 30/6/00 - Mounted the side bars onto the armour. Finished the stand and started work on the trolley. Started some initial plumbing work on the pneumatics - thanks to Julian Leeming at Mission for sourcing the 1/4" piping for us... 1/7/00 - Bought some bolts and some plastic tube (RC aircraft control snakes) for the aerial. Stripped the chassis, moved the gas supply tanks, removed the surplus buffer tank and did a lot of work on the pneumatics plumbing. Finished building the trolley. Made a box for the battery charger. 2/7/00 - Bought some large hose clips for the gas tank mounts, and modified the chassis so the tanks fit properly. Built the venting tap mount, thought about the removable link mount and the receiver/aerial positions. Completed the spike guards. Dave put a 4mm socket in the wrong place on the receiver box, modified the power supply and started modifying the decoder box. 3/7/00 - Tried to buy more crystals for the dual conversion receiver - but Inwood didn't have any in. Finished the gas tank mounts, and cut off the now redundant valve mount. Started making the receiver/aerial mount. Worked on the battery charger, while Dave completed the calibration of the decoder box. 4/7/00 - Phoned the Peterborough model centre about crystals - they only have the ones we have already got! Ordered yet more bits from Farnell... In the evening added extra battery compartment stiffening to the chassis, welded in the removeable link mount, worked out the aerial mounting, and figured out the hole in the armour for access to the pneumatics taps and removeable link. Dave worked on the chargers... 5/7/00 - Bits from Farnell arrived, but still no regulator... Worked on the aerial/reciever mount and the hand access hole. Looked at what connectors we still need to finish the pneumatics system. Dave continued work on the charger. 6/7/00 - Dave finished the charger, built the removable link, serviced the speed controller and set the current limit up to 75A. Bryan and I finished the electronics boxes mounts, hand access hole in the armour plus flap, and started reassembly of the chassis. Got the aerial mount 90% finshed.

7/7/00 - Our in-robot regulator finally arrived! Also bought some burst valves, a tank head and some compressed gas stickers for our cars. Plus another J&L order arrived... Spent the evening preparing for Robots@War tomorrow, finishing the aerial mount and wiring.

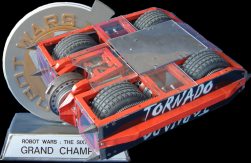

8/7/00 - We went to Robots@War at Wilsons Day 2000, for Tornado's first battle - see our event report. This was one of the longest days we have put in so far - 18 and a half hours - as we stayed on at Dave's afterwards doing captures for the website!

10/7/00 - Went to the Kart track after work to look for tyres, as we forgot yesterday, and it was a wet meeting - but there wasn't any. Reweighed the still-assembled robot (after Robots@War) to see what weight we have left for repairs and strengthening - according to Dave's bathroom scales we are at just under 74kg. Once all the pneumatics parts and extra steel were added, it put us up at about 79kg... We are definately going to have to go for one valve now, and having seen how small our ram is compared to what most people use, we must conceed that our weapon is now only going to be a token item... we have some big ideas for next year though (having seen Chaos 2 and 101)! Spent the rest of the evening stripping the chassis. The damage is a lot less than we feared - just that one bar needs replacing. Of course the spikes need something doing too... Bryan started using a hot air gun on the armour and amazingly, most of the larger bends and bashes popped out! Dave tested the electronic system, and it is all still working fine...

11/7/00 - We reckon that Dave's scales are a bit high reading, as Bryan weighed himself on the digital ones at work, and came out a couple of kilos lighter. Our audition forms from Mentorn turned up - ours is the 1st August. Replaced the bent chassis bar in the evening - the chassis sides were bent in 2mm, so they got knocked back out again. Also removed the damaged front spikes - we will replace them with something stronger and removable (hence replaceable!). Dave worked on the electronics, locating the drifting problem and upping the current limit (to 125A). Bryan finished taking the bends out of the armour with the hot air gun, built the charging system, and completed the final plumb of the gas supply tanks. 12/7/00 - Ground down all the welding did yesterday, added some more uprights to the front of the chassis, and finished off the battery compartment strengthening. Bryan made up some more battery compartment panels, while Dave finished our failsafe indicator light, redesigned part of the decoder and repaired our second remote. 13/7/00 - Rung Mentorn/Derek Foxwell during the day - found out details of the arena and weapons charging. Did some more grinding, and a little bit of work on the new front spikes. Made an insertion tool for the removable link. (It was one of Daves film nights, so we didn't get a lot done!) 14/7/00 - Bryan annealed the welds on the chassis, and started doing the pneumatics plumbing. I went home to Kent to collect some bits for the robot and show the Robots@War video to as many people as possible. Reactions varied from very enthusiastic to not being bothered to watch it (mainly due to hangovers...). 15/7/00 - Bryan and Dave went shopping in the morning, buying loads more bits and pieces, including more dual conversion crystals, and a couple of car jacks from a scrapyard, to make into chassis spreaders (in case Tornado gets bent again...). Did the last few welds on the chassis, ground them down, drilled out the new bar and welded the armour mount nuts on. Built a tool to help us remove the batteries. Dave solved the trimming problem - the transmitter overloads the receiver when very close, affecting its output slightly. Thus setting the trim up with the transmitter a bit further away seems to solve the problem... Also Dave got started on modifying the battery charger regulator circuit. 16/7/00 - Did some work on our logos/stickers. Built the two car jack chassis spreader tools, added some bars to the trolley (so it will carry our toolboxes if necessary), fixed the punctured inner tube, and did some modifications to the armour. Dave worked on the chargers, and started work on the backup speed controller. Bryan got stuck into the pneumatics, and by the evening we able to test it all - firstly we found that our 1000 psi burst valves are more like 250 and 350psi, secondly we found a few leaks, and thirdly... it works brilliantly! The fast exhaust goes off with a big bang, and the ram flies out too fast for us to see. The return is nice and controlled, using the smaller bore piping. We are very happy, as we have a nearly complete pneumatics system now! 17/7/00 - Bought some more paint for the trolley, tools etc. Looked for replacement burst/safety/relief valves - but we are having real trouble finding anyone who can sell us some! Getting 800psi ones for CO2 is no problem, but we would like to run on nitrogen, because we are worried about liquid getting past the regulator and bursting seals in the low pressure system... As a contingency we could put our 250psi on the low pressure side and one of the 800's on the high pressure, and run with CO2 - but we'd prefer not to... Derek Foxwell says we are the only team he has heard of that are having trouble finding these things - but then again most people are using CO2. We hope that other people are not neglecting their burst valves... Spent the evening reassembling the robot. 18/7/00 - Decision made, we are going to run with CO2 after all, using the 250psi pressure relief valve to protect the seals after the regulator. Also it seems we have a bit of a breakthrough - a fire extinguisher company (Newflame Fire Equipment & Maintenance Co.) in Peterborough has offered us a look in their scrap bin - they have said "anything they can do to help...". Phoning round lots of companies has led us to believe that 1000psi small plug size burst valves (same size as you see on CO2 fire extinguishers) can not be bought nowadays - one company told us that they would not want to sell them if they did, because if they came unscrewed, they would probably kill someone... Pressure relief valves do exist, but they are big heavy things (probably so they can't fly about) and they are expensive. For this reason, and for the fact that CO2 gives many more shots for the same tank volume, we feel that CO2 is now the only practical gas for Robot Wars. It's a lot safer too - direcly connect your CO2 tank to your cylinder - and you can only get 750psi, with nitrogen, you could blow your tanks up quite easily... Cut some steel bar and tube for the new front spikes at work. Bryan took the relief valves off of an old oxygen regulator, and tested those - they hold at 900psi (we were trying 750 but Bryan turned the shut off valve the wrong way!), so we shall use these on the supply tanks. Finished reassembly in the evening, and did a bit of weapons testing - it went straight through a stack of plastic speaker frames from work, but the system leaks so much that we only got the one shot at high power! Bryan has some work to do.

19/7/00 - Went to visit Newflame in Peterborough. The manager, Steve, gave us the head from a big extinguisher, including a burst valve rated to ... 190 bar! So much for "they don't exist"! Tried pulling my car (750kg of Fiat Uno) and it was comical how easy it was! Took Tornado out for some testing, this time at the closed down Little Chef - managed to finish the set of batteries we started at the cafe, and half use another set, with a total runtime of about an hour... We dropped a chain again, on the same side as before, but yet again we think it was due to a stone, and we had the tools with us to fix it. Unfortunately towards the end a drifting problem manifested itself, looking like we had blown half the fets on the speed controller. 20/7/00 - Stripped the chassis. Bryan continued work on the pneumatics. Contacted Dragonfly for a quote on our stickers/sweatshirts. 21/7/00 - Dave worked on the electronics - there is nothing wrong with the fet bank, and the drifting problem is due to the transmitter - the pulse width varies slightly with battery voltage! Thus after a lot of driving, as the transmitter batteries start to drop, the trim will appear to drift severely. Dragonfly got back to us with a quote ... on Bryans mobile while we were going round the off road course at Billing (the Land Rover show). Probably the most surreal phone call I have ever taken (revving diesel in background, one moment looking at the sky, the next at the ground) - and with a quote of nearly £400, not one that was welcome! 22/7/00 - Managed to buy quite a few tools from the stands at Billing. Also got the phone numbers of several stickers/graphics places. 23/7/00 - Started grinding down the rear spikes on the chassis, making them square in section rather than round. Bryan continued with the pneumatics and made an adaptor for the slide hammer. Dave modified a sensitive trimmer pot in the decoder box. 24/7/00 - Dave got the backup speed controller running on the bench. Finished squaring off and hardening the rear spikes. Started cutting the replacement armour, cleaning the chassis and painting various parts of the pneumatics mounts. 25/7/00 - Cleaned, degreased and started painting the chassis - but ran out of paint! We used angle grinder brushes to clean it, and if you try them, beware, they're viscous buggers! Dave continued with the backup speed controller. Ordered the stickers for the inside of the robot from Applied Lettering, and our sweatshirts from Bourne Embroidery.

26/7/00 - Our lettering (stickers) from Applied Lettering arrived - all look excellent. Bought loads more paint at lunch. Spent the evening cleaning and painting the trolley and stand, while Bryan put the pneumatics system back in the chassis and Dave worked on the backup speed controller. The weapon is now fully working and reasonably leak free - fortunate, as Bryan is off to the Claircraft convention tomorrow...

27/7/00 - Sweatshirts arrived - they are excellent! Also got the paper templates of the logo printed - thanks to Neil Owen and Martin Cassey at work. Spent the evening working on the removable front spikes - and completing the painting of the stand and trolley. Dave continued work on the backup speed controller... 28/7/00 - Found out from Mentorn that the filming of the programme is due to be the 7th-14th of August. Got six of the spikes ground, and the mounting holes drilled into all 11 spikes and the chassis. Put the trolley back together. Dave continued the backup speed controller... 29/7/00 - Finished grinding the (removable) fixed spikes (managing to set fire to my jeans in the process!!!), painted the chassis, various metal parts, the slide hammer, the gas tanks and the spike guards. Unfortunately, ran out of paint again... Also broke the gearbox casing of one of our angle grinders - was swinging on it to get one of the cleaning brushes off - so took the gearbox off the old grinder we burnt out a while back... Plus had to repair the welder, Bryans die stock, and Daves workbench in the same day... Not forgetting setting fire to the rubbish pile whilst welding! Made up some spikes for the ram, and with the help of Dave's neighbour Kev, hardened all the removeable and ram spikes. Dave continued work on the backup speed controller - just the control board to build now.

30/7/00 - What a day! Today was crunch day - Tornado needed to be completed and assembled, and by 3am on the 31st, it was... Tasks completed included finishing painting, attaching stickers, changing tyres (to wets) and sorting wheels, attaching removable spikes, making replacement armour, the removeable link retaining bolt, reassembly, and basic on the bench testing. Dave abandoned work on the backup speed controller at about midnight, when it became clear that it would not be ready to test that evening. We loaded the robot, a few tools and the nitrogen cylinder into our cars to show everyone at work tomorrow. | Forward to next entry - Series 4 | |