|

CLICK ON THE THUMBNAILS TO VIEW A LARGER IMAGE | Back to previous entry - Advanced Plans | 6/2/00 - Started work on the chassis. Found it was necessary to strip the paint off the box section steel we bought for the chassis, which is a long and boring job with lots of Nitromors! Managed to make four of the main chassis rails, and weld them together with decent quality welds. Comparing our wheels to the space we have allowed for them, we don't have much clearance!

7/2/00 - Managed to measure our wheel bearings and intermediate bearings at work. Decided to widen the chassis, to fit the wheels in properly. Cut up what welded yesterday, and made and stripped the paint off most of the bars for the lower part of the chassis. 8/2/00 - Received an email from Display, offering a refund for the two dodgy batteries and a contribution towards our postage. Emailed Trading Standards for their advice, and got a call back. Emailed Display asking them to honour the offer they made us on 15/12/99. Spent the evening welding together the chassis parts prepared yesterday - and ran out of welding wire! What was done seems very strong and more than up to the job. Also Dave is making progress on the speed controllers. 9/2/00 - Gave the welding gas cylinder emptied last night to Bryan for the pneumatics. Managed to get some more welding wire, so spent the evening working on the chassis, and finished welding the bottom section. Got a reply from Display - basically they've ignored what I requested and apparently have paid a refund to my credit card. It's time to speak to Trading Standards again...  10/2/00 - Got an email at work giving the details of the refund from Display. Mailed Trading Standards regarding what we do next. Finally got round to finishing the Series 4 application form and sending it off. When I got home Mentorn had sent another one! Below you can see the images we sent to show Mentorn what we are thinking of:

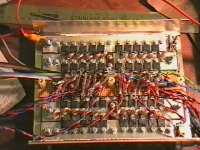

11/2/00 - Got the full gas cylinder from Bryan that he bought, to use when welding. Bryan has also got hold of most of the connectors and the hydralic hose for our pneumatic system. 14/2/00 - Gave Dave plastic for speed controllers, that I got hold of from ex-team member Gary. Discussed exact details of speed controller positioning and wiring with Dave, and we are both happy. Ground down the welds on the lower part of the chassis. It now needs a bit of strength testing... 15/2/00 - More Chassis work; cut and stripped a few bars. Strength tested the lower part of the chassis (large hammer). I am happy... 16/2/00 - Finished cutting and stripping bars for top part of chassis. The speed controllers are progressing, with several of the boards now being soldered. 17/2/00 - Welded upper part of chassis. Worked out control requirements with Dave - and the parts we need to order. 18/2/00 - Ordered loads of parts. 21/2/00 - Ground welds on upper part of chassis. Found it was a bit warped, so put that section over a bar and bent it flat with Dave and Andrew standing on it - if it can handle that lot then the whole chassis should be bombproof! Started stripping the bars for the uprights of the chassis. 22/2/00 - Finshed stripping the bars for the chassis uprights. Cut down the speed controller box, and worked out the mounting method for the speed controller. 26/2/00 - New rules arrived. No major difficulties, just a few minor changes that will affect us. We need to get a list of queries together however just to make sure that we are adhering to the rules. We still haven't heard back from Trading Standards, and getting these batteries sorted is becoming too much hassle, so we are accepting the refund that has been forced upon us, but begrudgingly. Hence we strongly recommend that you do not buy anything from Display. On another note, Dave is starting to assemble the speed controller. Note the seriously large bus bars and the huge pile of FETs!

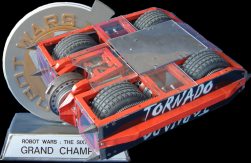

28/2/00 - Got four go-kart wet tyres from Paul at work. They're of a much softer compound than the slicks, so are probably better for us. Also they're a bit smaller, being only 4" wide rather than 4.5". Booked a team meeting for tomorrow. 29/2/00 - Team meeting - went through new rules and where we go from here. We need to clarify a few points with the technical advisors. Also Bryan is going into hospital for an operation on his knee, so work on the weapon will be stalled for a while. 1/3/00 - Mailed Derek Foxwell with our queries. 7/3/00 - Rung Mentorn re contracts - we have only received one pair! This is correct; they are only sending out one to the captain because of the huge number of applicants - the other team members will need to sign if the robot passes the audition. Also rung Derek Foxwell: strobes are fine, we must keep below the pressure limits for our pneumatics and we must have a metal cover for our spike. 8/3/00 - The pressure limits for our pneumatics may cause us a problem, so we will get all our tanks certified. Mentorn can't argue then! Spent the evening welding up the Bosch motors on the advice of the Killerhurtz team, and measuring up for our drivetrain parts. 11/3/00 - Paid a visit to the kart track at Kimbolton, in an attempt to get hold of some more tyres. Saw Paul from work, but in 2 hours only managed to find one pair of discarded front tyres! 12/3/00 - Returned to the kart track at Kimbolton. Today was race day, and we had much more luck. We found another 18 front tyres, all slicks.  13/3/00 - Spent my lunch break at work in the workshop - progress is being made on the parts that need to be made there. In the evening, stripped, ground and tidied the chassis uprights, plus prepared the chassis for welding by drilling some holes and stripping some light rust. 14/3/00 - Received spikes and wheel supports from workshop. Welded some of the uprights to the lower part of the chassis, and welded all of the spikes in. My welding is getting better! Started grinding the new welds down. Found that our bar won't go through the wheel supports, so returned them to the workshop. The pictures of the chassis below give an idea of what Tornado is going to look like.

15/3/00 - Finished grinding down welding did yesterday. 20/3/00 - Welded top part of chassis onto lower part. We've made a couple of progress targets for the robot - we want to have something moving about under radio control (in the proper chassis, not the mockup) by the end of the second week of April. We hope that's not a tall order! Dave is making big progress on the speed controller, having a motor running under radio control. However, he was having a few problems with the current limit, i.e. it was making the motor run away! 24/3/00 - Spoke to the guys in the workshop about getting our parts made. Agreed that if we don't make significant progress by the end of next week, we need to look externally. 26/3/00 - Added more uprights to chassis, and started work on battery clamp. Did more grinding. We need to get hold of the machined parts very soon or the chassis work will come to a dead stop... Dave solved a lot of the speed controller problems when he found a broken wire! 27/3/00 - Rang Derek Foxwell re the Kiel batteries. He told me that they are OK! (Note that since this time they have been banned, then subsequentially tested and they are now allowed!) Derek is only worried about spills from batteries because 1) he doesn't want to have to clear up acid, and 2) apparently there are often people working under the arena during the battles! The workshop at work is very busy now, so I borrowed hand tools to modify the wheel mounts. Took no more than 20 minutes to do it myself! Also finished off the battery clamp and box. 28/3/00 - Welded the wheel mount uprights into the chassis. Got a written reply from Derek Foxwell to the questions we asked on the 1/3. 30/3/00 - Ground uprights down. Dave has run the speed controller at 36V for the first time - and blown it up! Another rebuild is needed!

31/3/00 - Spoke to the workshop guys again; it doesn't look like they are going to be able to make our parts in time, so we need to start getting quotes! 3/4/00 - Measured the chassis for armour and started work on radio control handsets. 4/4/00 - Took the chassis into work. It has provoked some interest, so we may be able to get the parts made after all! Started ordering the required raw materials. 5/4/00 - Ordered the aluminium plate for the drive plates, 17mm rod for the axles, and polycarbonate and nylon for the armour and drive blocks. 6/4/00 - Spent lunch at work getting the steel tube and bar to make the axle spacers and supports. Bryan cut them to size in the evening in the workshop, just the holes need drilling out for the axles. 7/4/00 - Spent lunchtime today getting the aluminium sheet for the drive plates. Cut the sheet into squares, and drilled 16.5mm holes in bar sections in the workshop in the evening. These parts are the axle mounts that will be welded into the chassis - but we need a 17mm drill to get the axle to fit, and our workshop doesn't have one! Also asked my graphically talented friend Neil to produce us a logo, with an aim to eventually getting some T-shirts printed up for the filming. 8/4/00 - Helped Dave convert the R/C control handsets. Bryan got hold of a 17mm drill so we can finish the axle mount inserts. 9/4/00 - Took another trip to the Kart track at Kimbolton. Obtained another 21 front tyres, including another pair of wets! This gives us 49 tyres, 6 of which are wets... Dave has been working on the failsafes, with a new circuit which is much more reliable than the old one.

10/4/00 - Our logo is progressing - Neil has had some good ideas. Looked at what needs doing to the gears, and Bryan is confident that it will not be too much trouble. Started work on them in the evening, but got thrown out of the workshop earlier than we were expecting, so we didn't get a lot done! We also found that our supposed 7/8" bar is actually 22.00mm, not the same thing, and very annoying! 11/4/00 - Stayed behind in the workshop after work. Got 8 axle inserts and 6 drive plates done, plus machined clutches down to enable fitting to spur gears. But when we tried to drill the clutches, nothing would get through them - they are made of extremely hard material. 12/4/00 - Found out that insurance is a problem at work, so we can't stay on late in the workshop any more until it is checked out. 13/4/00 - Plastics arrived from Plastim and more 17mm steel bar plus hardened steel drill bits... 14/4/00 - Cut nylon rod for drive blocks, 17mm bar for axles and 22mm bar for inserts during my lunch break. Discussed what we can do outside work with Bryan. 15/4/00 - Asked Gary's (ex-team member from back home in Kent) Dad if I could use his lathe, and very helpfully he agreed. Bryan obtained a pillar drill, 1/4" bolts (which are actually M6!) and 1/4" drill. 16/4/00 - Made four drive blocks, six axles, 12 chassis inserts and 4 intermediate blocks on Gary's Dad's lathe. Bryan managed to drill the holes in the clutches and spur gears using the hardened drill bits, and Dave started building the receiver decoder board. 17/4/00 - Found out that the insurance problem at work "stands" - i.e. we are not supposed to do anything of our own at work! Bought two extinguishers from Halfords, and some 1/4" bolts from West End DIY. Spent the evening welding the wheel mount inserts to the chassis - until we ran out of gas - and Bryan planned the pneumatics, including emptying the resevoir extinguishers purchased earlier. They are much lighter than our original resevoirs (about 400g each)! Dave continued work on the speed controller. Also found that our 1/4" bolts from Mackays are definately M6, so our advice (after also the 7/8" bar being 22mm) is if you buy anything from Mackays (of Cambridge), take your verniers!

18/4/00 - Bought more proper 1/4" bolts and welding gas at lunch. Bryan managed to find some 1/4" dowel pins also, but these simply dropped through the holes in the clutch and gear! Managed to complete welding the inserts in place in the evening, plus ground them also. Bryan drilled the drive blocks, and we found a set of tyres and started to assemble the wheels. We managed to finish one, but the drive sprocket was found to be a good few milimetres out when we put the wheel into the chassis. Dave managed to blow the speed controller up again - this time with all the protection he could think of on the FETs - and he is starting to run out of ideas!

19/4/00 - Bryan got Nitrogen gas cylinder for pneumatics. Managed to rebuild wonky wheel straight after drilling drive blocks out, and get a second wheel built. Bryan worked on the pnuematics and cut studding down for the wheels. Dave had the speed controller running for the longest time so far without it blowing (yet) - progress! 20/4/00 - Finished building the wheels up, and got them into the chassis. 21/4/00 - Spent most of the day fixing my car exhaust - and used the robot chassis as a wheel stand, as my axle stands are still in Kent! We put about 200kg onto one side of it, which is getting on for the weight of Killalot. Worked out exactly how the motor and intermediate gear will be fitted, and Dave got the speed controller running properly with one FET.

22/4/00 - Spent the morning going to Stratos to get a chain breaker for the kart chain, and Bryan went to Securicor, Mackays and Machine Mart for various tools and parts. Chassis progress consisted of getting the chain cutouts into the chassis, the axle stops in place, and making a slide hammer for removing the axles. Bryan sorted out much of the pneumatics, cutting correct threads in various parts, rebuilding our welding bottle taps, and putting together many of the connectors. Dave rebuilt the speed controller, getting it working such that we all saw it going delivering 50 amps into a starter motor! 23/4/00 - Made guards for the spikes (as Bryan and I were fed up with taking chunks out of ourselves), and made the kart chains up to correct length. Measured and made up the motor mount plates, and started aligning the gears, motor and intermediate shaft on one side of the chassis.  24/4/00 - Built, aligned, and welded into place the motor and intermediate gear mountings on both sides of the chassis, all apart from one insert. We need to get several bits machined now - which might be difficult - such that we can finish the drive system! Dave wound the speed controller up to the full 150 amps, driving into a large (6" diameter, 6" long, 2" bore) air cored inductor from an old UPS which we got from the scrapyard. He reckons it makes a good model of a stalled Bosch, but it's even better as an electromagent, dragging tools across the desk! (It gets a bit hot too!) Dave thinks the speed controller is sorted now - the problem was in getting the signal to the gates of the FETs, and the change of layout solved the problem.

25/4/00 - Got the go ahead from Richard in the workshop, to help us by making some of the more important parts himself! This is great news and means we will be back on track for having the robot finished in time. Put both intermediate axle inserts into the chassis, started on the restraining hook, and sorted all the parts (including the pneumatics) for work on in the workshop. Also tried the oxygen regulator we have on the Nitrogen cylinder - and it appears to leak profusely! 26/4/00 - Found out that a proper nitrogen head will cost a whopping £200! Hence we shall need to make a flow limiter for decanting. Finished welding in the securing/towing bar, and ground down all the welding. Dave is completing the speed controller rebuild, and got it built and tested on both channels. Assembled parts for working on tomorrow night. 27/4/00 - Stayed behind in the workshop with Richard and Bryan. Richard machined up the gears and fitted the pinions to the motor shafts (using a solid 5mm dowel pin), while Bryan turned up axles and sleeves, and cut down material for the nitrogen flow restrictor. I deburred things and hoovered up... We returned to Daves afterwards to find that the gears had been machined on the wrong side, and none of the clutch holes line up! The solution is to re-drill the clutch, but we need to make an alignment tool to do that. We also weighed the gears, finding they have been reduced in weight from 1350g to just over 700g! Also Bryan tapped out the intermediate axles.

28/4/00 - Managed to get an alignment jig made in the lunchbreak at work. Also cleaned up and drilled the flow restrictors, and tapped out the gas bottle adaptor. Drilled out the new clutch plate holes using the jig, and put one side of the drivetrain together in the evening. Connected it all to the speed controller and got it running off the ground. Also weighed everything in the chassis, and went back and checked the budget - we are 5kg overweight!

29/4/00 - Decided to check the torque available by connecting the motor directly to one 12V battery - this would give a stall current of about 70amps. This showed that our speed and acceleration (only on 12V) is impressive - but when we attempted to stall the drivetrain, the intermediate pinion slipped on the chain! This appeared to be a major problem at first, but we worked out a way round it - we just need to add an idler wheel so that more of the chain passes round the clutch pinion. After yesterday's discovery of our weight problem, everything was weighed (by putting the chassis onto the scales and then every other part we will be using on top of it). It seems that we will be OK, but it is going to be close! Started work on the rear motor mounts. 30/4/00 - Started welding the front mounts for the pneumatic ram into place, only to find they were positioned wrong and had to be cut out and done again! Also welded in the rear motor mounts, and started work on the rear ram mount. Made decisions on how the mounts for the tanks will be made - more welding... 1/5/00 - Went looking for paint, and bought some M8 studding for the ram. Also got some driving practice by getting a couple of our radio controlled cars going again! Continued with the rear ram mount, and started on the tank mounts. Dave has the second decoder board nearly complete. Also found a nearby but deserted testing ground (as just ordinary R/C cars attract an audience) for driving practice and proving of the chassis once it is running.

2/5/00 - Got hold of paints - bright red for the chassis, and bright blue for various odd bits that need painting too. 3/5/00 - Lots of parts arrived from RS, Farnell, Maplin and J&L. Bryan got the pneumatic ram machined at lunchtime. 4/5/00 - Bryan started work on the spikes for the pneumatic ram at lunch. In the evening we started welding in the pneumatics mounts, painting and assembling the pneumatic ram and working out where the final electronics boxes will go. Also found that the auditions will be 24th July-12th August: loads of time! 5/5/00 - Bryan made the inserts for the idler axles during lunch at work. 6/5/00 - Not much progress today on the chassis, other than looking at what still needs doing in the machine shop. Dave did more on the decoder and controller boards, plus completed building the speed controller.

7/5/00 - Today the mounts for the pneumatic ram were completed, and work started on the mounts for the speed controller. Dave has been building up the transmitter boxes. Also tried out our testing area - apart from a few dog-walkers, it was pretty much deserted - so we got some more driving practice!

8/5/00 - More work on the pneumatics mounts, and finshed the speed controller mounts (2 sets - one for the main controller and one for the backup). Started fitting the pneumatic system - and for a while it looked like we would have to leave out one resevoir and one valve - but Bryan turned a valve round and it all fitted again! 9/5/00 - Bryan cut down and drilled the idler shafts, plus pressed on the bearings during lunch. Bryan tapped the holes in the idler in the evening, while I made the chains to length and trial fitted the idler - it looks like it's going to work OK. Dave continued on the decoder board box. 10/5/00 - First spikes completed at work; we shall use them for testing as we forgot the return taper, and we are unsure of the best piercing angle (these have been cut to 15 degrees). 11/5/00 - Welded one of the new idlers into position, and started modifying one side of the chassis so that the chain ran round OK. It looks like it's going to work, although the bearing isn't exactly in straight... a chain guide may be required. 12/5/00 - Made up speed controller mounting strip, worked out how the chain guide will be fitted and made up the mounts for it. Lots more parts arrived... 13/5/00 - Made progress on the chassis modifications, welded in the speed controller mounting strip and also re-welded the axle stops. Also got some more driving practice... we are beginning to think that the area we have found is too small, but we may have already found a replacement, at an abandoned truckstop cafe beside the old A1. 14/5/00 - Tried out the new testing area (the old cafe). It's brilliant - big enough, and with loads of junk to test the weapon on and push around. The only thing it lacks is an area free of dust that we can get the cars onto (for pulling tests) - but a closed down restaurant just up the road has a car park that is ideal! Welded in the chain guide mounts, and the lower rear reservoir mounts. 15/5/00 - Made up the mounts for the front of the reservoirs. More driving practice at the old cafe. Dave has pretty much completed the decoder box, and is moving on to the power supply box... 16/5/00 - Drew up a big version of the "comedy flying cow" part of our logo (you've seen Twister, right?). Dismantled the mockup, as we're not likely to use it now. Also found the scales we lost way back in January, in amoungst the RC Car bodies box!!! 18/5/00 - Dave has gone away on holiday - storm chasing in America! (Hence the robot name...) We have a key to his garage though, so work can still continue, (but we won't have any more pictures until he gets back). Welded in the rear supply tank mounts (to the front of the chassis), and the front mounts for the reservoirs. Also fitted the lower part of the front supply tank mounts, and one of the valve brackets. | Forward to next entry - The Final Push | |